Dentos Dental Care

About Dentos

Dentos is a Dutch brand of dental care products. We supply our customers with the highest product quality at the lowest possible prices. We offer development, production, packaging, transport, storage and distribution services for both private label and Dentos label. Our main customers are supermarkets, drugstores and department stores in Northern Europe.

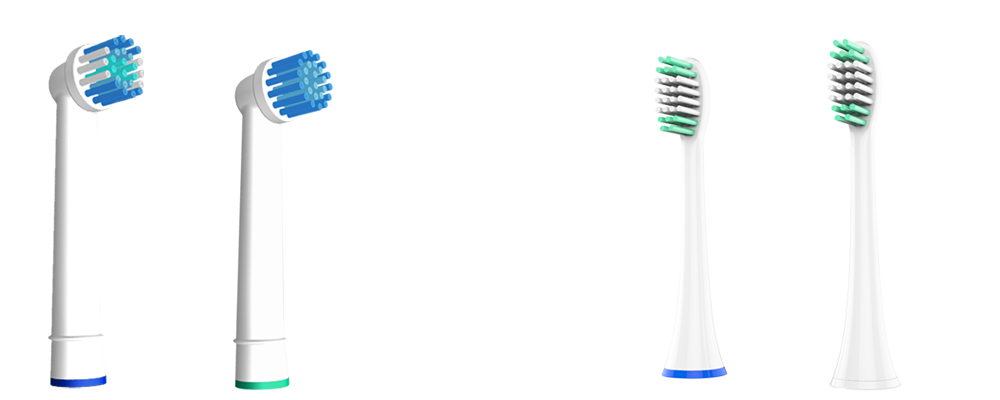

Brush Heads

Our most popular products are compatible replacement heads for electric toothbrushes of Oral-B and Philips. Our Pro Clean, Sensitive Clean and Kids Clean heads fit perfectly on Oral-B handles and our Pro Sonic are compatible with Philips Sonicare. All of these replacement heads are made of the finest materials and therefore of excellent quality. They make a great private label product and are the only quality alternative to the expensive branded ones. We invite you to read more about our quality and hygiene standards to find out why.